PTM and its Products

What PTM GmbH stands for:

As a specialized manufacturer of high-quality stirring technology with many years of experience in the toughest applications, we know the requirements for sophisticated technology in biogas plants in detail. With this user knowledge, a series of agitators was developed that combines maximum efficiency with absolute durability.

In order to achieve this, we rely on our vast experience, the best materials, and constant regulation of our products.

Our Development – Propellers made from Physinit©

Agitators in biogas plants are exposed to special and harsh conditions. In practice, long fibers and mineral components, especially sand and stones, often cause damage to propellers after a short period of time. As a result, this leads to short lifetime and high costs from repairs or replacement of the existing agitators. In this context, a new generation of propellers made of highly wear-resistant Physinit© was developed, and is proven to be far superior to metallic and fiberglass materials. This solves the fundamental problem of propeller durability and achieves service lives that are well above the market level. In addition, the hydraulics ensure efficient and effective stirring results, even for the highest demands. This is particularly significant for retrofitting of agitator technology that is already in use in order to further improve the service life of agitators.

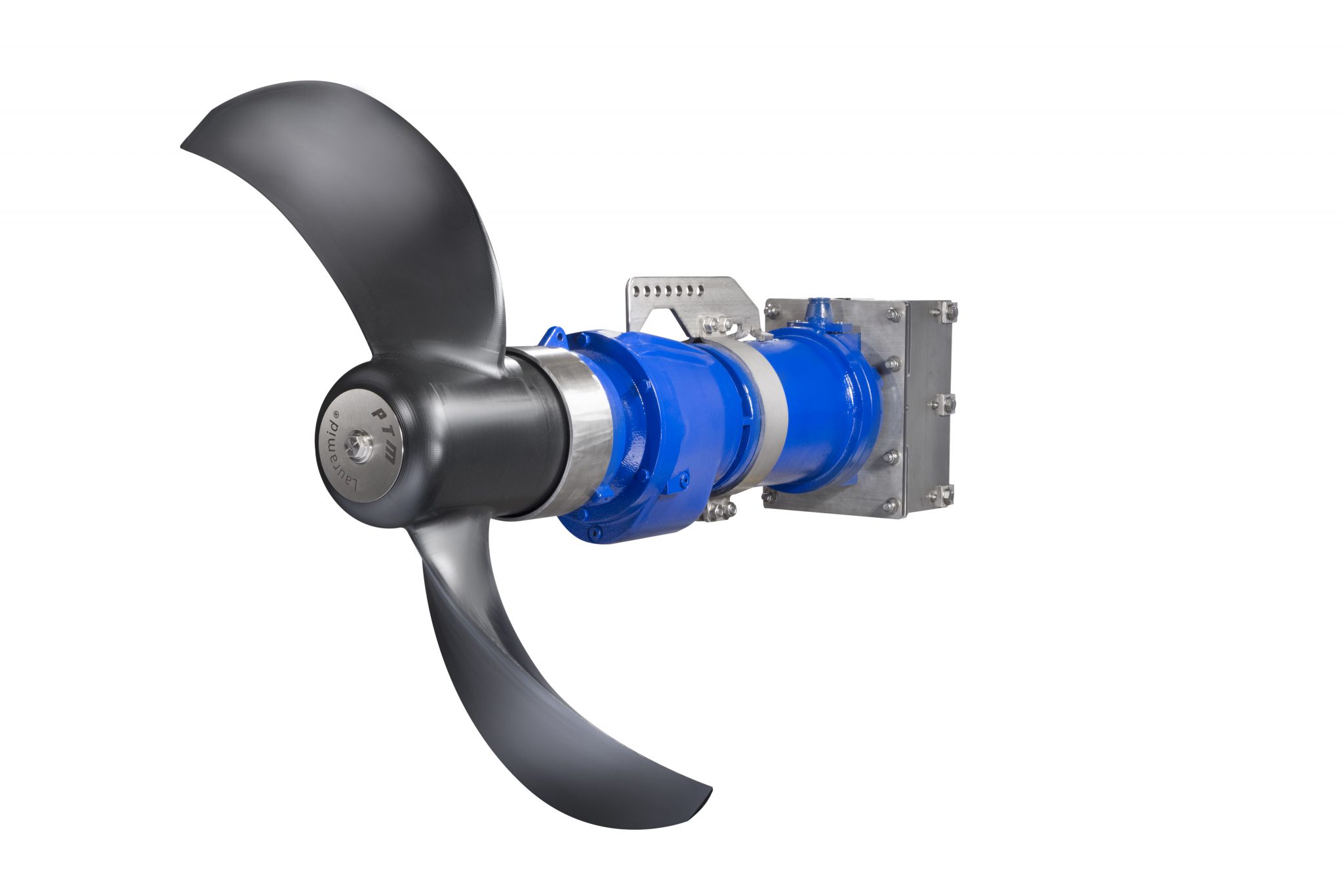

PHANTOM – the Agitator

The PHANTOM is the most efficient submersible mixer in its class. In demanding applications, it is superior to all other agitators in every aspect of flow generation whether it is slow-mixing or generating turbulence. Yet, its unsurpassed service life and high thrust/performance ratio are no coincidence. They are simply the result of the interaction between a large number of optimized components.

Our attentiveness to details makes an agitator a PHANTOM!

Advantages of the PHANTOM agitators at a glance

- Extremely wear-resistant propeller made of Physinit© offers abrasion and corrosion resistance with the highest thrust-performance ratio

- Hardened counter ring carrier protects the mechanical seal from fibrous materials

- Covered double mechanical seal resists intrusion of solids and fibers

- Guide bracket with movable rollers ensures free mobility even when burdened

- Motor with high reserve offers full power even in high-temperature operation

- Large cable cross-section noticeably increases the service life of the cable

- Precision bearings guarantee smooth operation even with frequent load changes

OAreas of application of the PHANTOM-agitators

- Suitable for all heavy-duty applications - e.g. in Biogas plants (Fermenter, post-digesters, digestate storage) and drilling suspension.

Product overview

PHANTOM 1000 – horizontal submersible mixer for Biogas

| Area of application: | Mixing pit, Fermenter, Post-digester, Digestate storage |

| Pumped medium: | Biomass substrate |

| max. permissible temperature: | 60 °C |

| Propeller speed: | 157-183 min-1 |

| Motor power P2: | 16 kW |

| Design: | Physinit© |

| Propeller diameter: | 1.000 mm |

| max. thrust: | 3.762 N |

| Ex-Protection: | II2G Ex d IIB T3 |

PHANTOM 1400 - horizontal submersible mixer

| Area of application: | Mixing pit, Fermenter, Post-digester, Digestate storage |

| Pumped medium: | Biomass substrate |

| max. permissible temperature: | 60 °C |

| Propeller speed: | 90-115 min-1 |

| Motor power P2: | 11-16 kW |

| Design: | Physinit© |

| Propeller diameter: | 1.400 mm |

| max. thrust: | 4,990 N |

| Ex-Protection: | II2G Ex d IIB T3 |

PHANTOM 2500 - horizontal submersible mixer

| Area of application: | Mixing pit, Fermenter, Post-digester, Digestate storage |

| Pumped medium: | Biomass substrate |

| max. permissible temperature: | 60 °C |

| Propeller speed: | 46 min-1 |

| Motor power P2: | 9 kW |

| Design: | Physinit© |

| Propeller diameter: | 2.500 mm |

| max. thrust: | 5.860 N |

| Ex-Protection: | II2G Ex d IIB T3 |

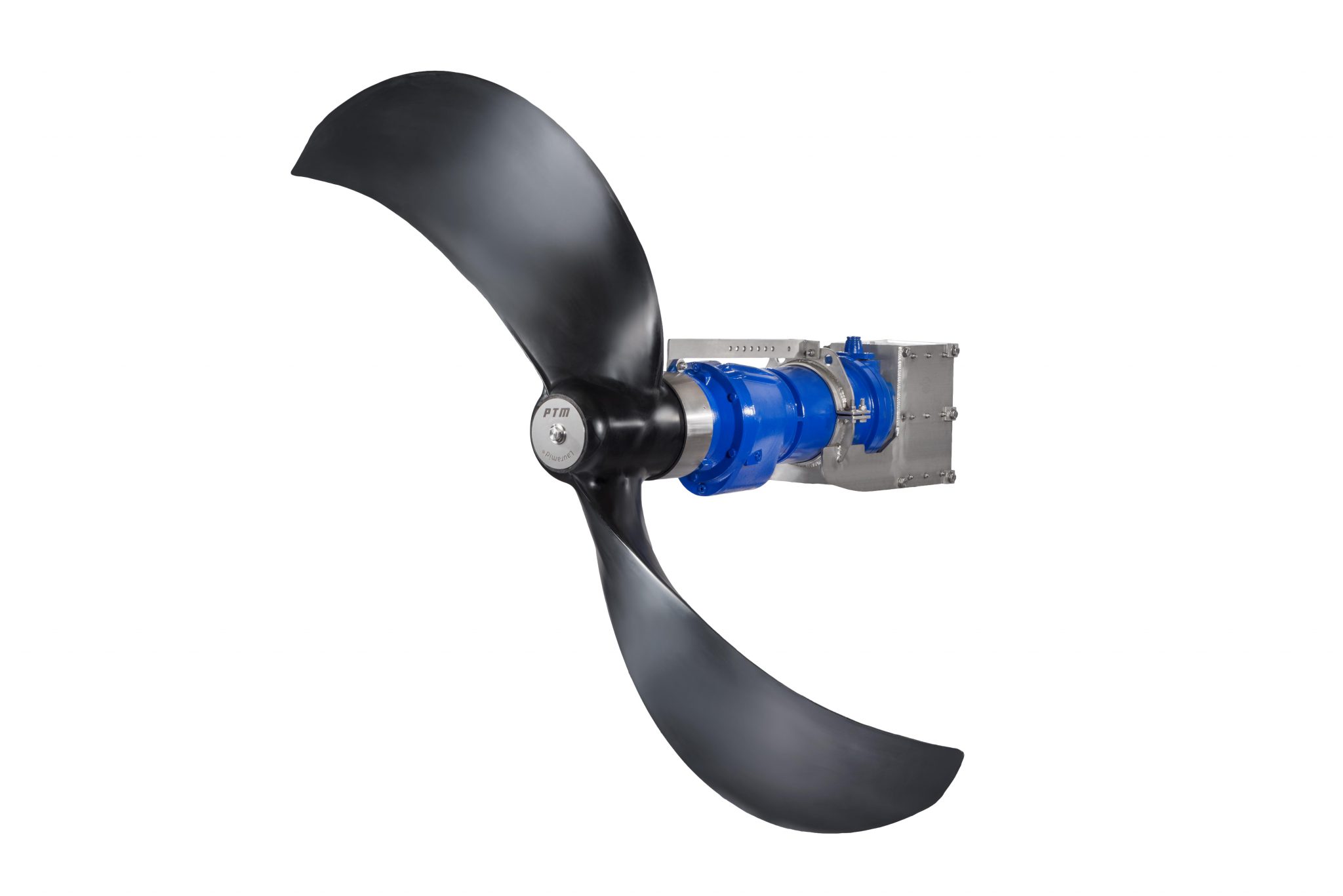

TYPHOON –The Specialist

The compact Typhoon is ideal for turbulence-intensive mixing applications in low-viscosity fluids with abrasive components. Its propeller is made of highly wear-resistant Physinit©, which was developed with the aid of the most modern computer-aided simulation processes and was perfected in empirical practical tests. Like the Phantom series, the TYPHOON has a double mechanical seal and bearings that are lubricated for life. Thanks to its direct, gearless drive, the TYPHOON agitator has a small, compact design and can be easily operated without a soft start or frequency converter. This makes the Typhoon agitator the ideal choice for fermentation residue storages or mixing pits.

Advantage of the TYPHOON at a glance

- Propeller made of Physinit© - optimized propeller made of wear-resistant high-performance plastic for perfect stirring results

- Double sealed - two mechanical seals made of resistant silicon carbide

- Direct drive - compact design and no gear wear

- Low maintenance - up to 16,000 operating hours without an oil change

- Ex protection - ATEX as standard

- Monitoring – total of 3 temperature and humidity sensors for motor monitoring

- Perfect protection - longitudinally watertight, encapsulated cable entry to protect the motor from moisture - easy cable replacement for servicing without special tools

TYPHOON - horizontal submersible mixer

| Area of application: | Mixing pit, Digestate storage |

| Pumped medium: | Biomass substrate |

| max. permissible temperature: | 40 °C |

| Propeller speed: | 475 min-1 |

| Motor power P2: | 10 kW |

| Design: | Physinit© |

| Propeller diameter: | 650 mm |

| max. thrust: | 2.410 N |

| Ex-Protection: | II2G Ex d IIB T4 |

Our service Portfolio for you

- Complete technical and commercial know-how for agitator design and assembly

- Feasibility studies and concept development for new systems and system repowering

- “Computational Fluid Dynamic“ (CFD)-Flow simulation

- Rheological behavior investigations

- Construction and static verification of installation sets for special applications

- Large storage of agitators for quick delivery time and fast responses